Training for Success: How WRTP|BIG STEP is Strengthening Milwaukee’s Skilled Trades

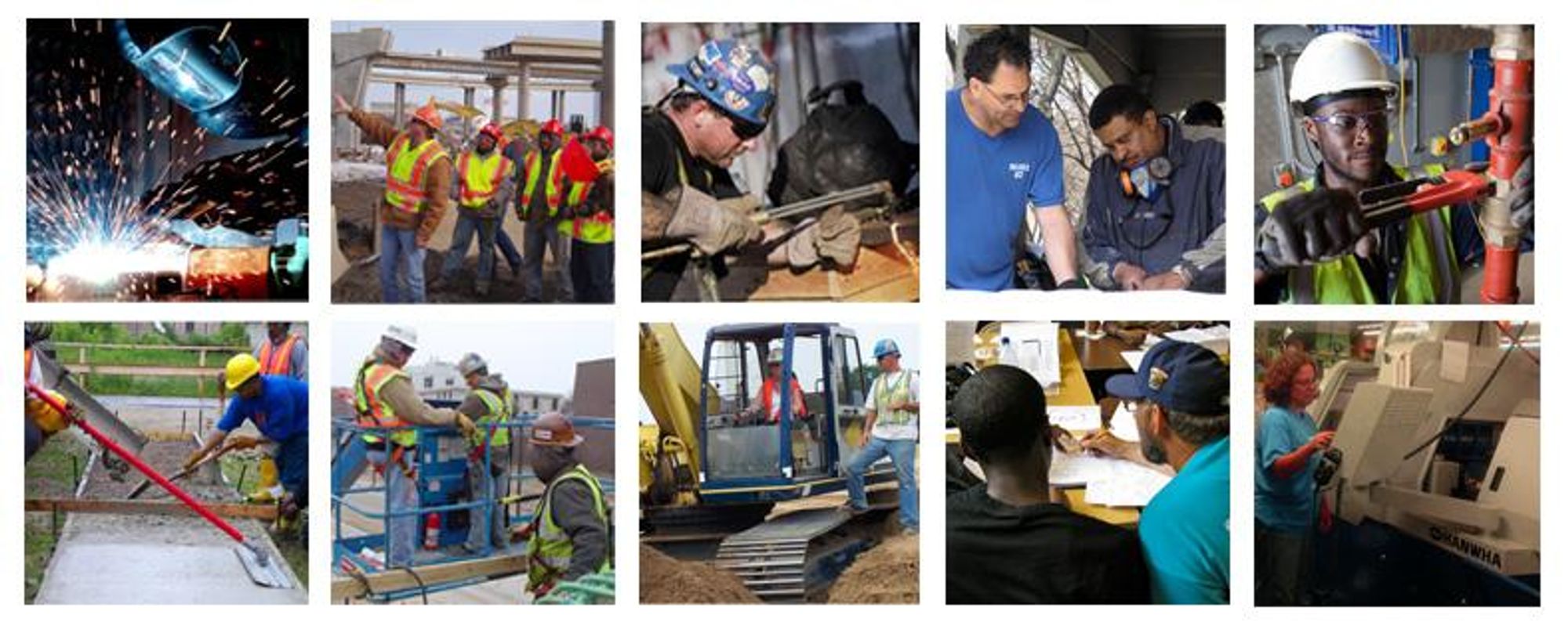

Industry Led, Worker Centered, and Community Focused.

Brief Introduction, History, & Background

Building Industry Group and Skilled Trades Employment Program (BIG STEP) was founded in 1976 by representatives of the building trades in Milwaukee. BIG STEP’s main goal is to increase the number of young adults, women, and people of color workers in the building trades. Through a Department of Labor grant in 2002, BIG STEP was able to partner with the Wisconsin Regional Training Partnership (WRTP) to develop new employer-driven work readiness initiatives. From the beginning of their collaboration, the two organizations developed multiple ways of supporting each other's work: creating funding opportunities for both organizations, developing strategies for engaging with unions and employers, and increasing efficiencies in training programs. They would eventually merge their boards and organizations in 2014.

WRTP was started in 1992. A wave of retiring workers, increased demand for manufacturing skill sets, and shifting global and local supply chains were impacting Milwaukee’s industrial base in the 1980s. These factors pointed to the need to create two workforce development strategies: one that would help incumbent workers develop and maintain skills, and one for workers without manufacturing experience or knowhow. The Commission on a Quality Workforce, a State of Wisconsin initiative, studied the problems and recommended a partnership be created that brought together labor, business, and government. WRTP formed in response to the commission's recommendations. They received funding from the Annie E. Casey Foundation and took up the task of establishing a manufacturing training program for former welfare recipients and other low-income central city residents to gain access to family-sustaining jobs in manufacturing.

With support from former governor Jim Doyle in 2006, WRTP|BIG STEP established the Center of Excellence for Skilled Trades and Industry (COE) to scale and create programs in response to the reemergence of a skills shortage in Milwaukee’s industrial sector. The COE is located in the center of Milwaukee and serves employers, unions, current workers, job seekers, and community partners. The COE acts as a hub serving as a clearinghouse for job-ready candidates looking for careers in manufacturing, construction, and other related fields. Candidates can begin their career pathway there by learning about opportunities, and expectations, for careers in manufacturing and the skilled trades, learning about job placement processes, and applying for and participating in training programs. The COE also acts as a conduit between employers and newly-skilled professionals. Over the course of WRTP and BIG STEP’s combined histories they have helped lead the renewal of the manufacturing base in the Milwaukee area while increasing people of color and female representation in the city’s skilled trades and manufacturing.

Quote:

“When we started designing the IMT apprenticeship we brought all kinds of manufacturers to the table: food processing, motorcycle making, etc. It didn't matter if they were in plastics, metal, or wood, they were all at the table. We really wanted to make sure they were all at the table because we wanted to design something as a standard core curriculum for all advanced manufacturing.”

-Rhandi Berth, Chief Innovations Officer

About the Industrial Manufacturing Technician apprenticeship program

WRTP|BIG STEP uses workforce development to help stabilize individual manufacturers by helping them keep and upskill their employees. They are helping Milwaukee’s regional economy by creating strategies which allow them to work with a number of manufacturing businesses, regardless of their specific sector or expertise. Different from most workforce development programs, they use a “reverse model” where WRTP|BIG STEP identifies immediate needs and job openings in manufacturing businesses and then tailors apprenticeships and training programs to address those needs. They work with employers and unions to complete needs assessments — through a one-on-one interview with the employer — to find out who's hiring, laying off, or growing, who's investing in their workers, and who’s struggling to find employees. WRTP uses the collection of assessments to understand how the manufacturing ecosystem is working.

WRTP|BIG STEP’s newest support for helping employers respond to skilled worker needs is the Industrial Manufacturing Technician (IMT) registered apprenticeship program. WRTP|BIG STEP worked with employers, unions, and the Wisconsin State Labor Workforce Office to create the IMT apprenticeship. What makes the IMT apprenticeship different is that it was designed to cut across different types of advanced manufacturing sectors and jobs. WRTP|BIG STEP was able to develop the apprenticeship by bringing diverse manufacturers to the table who had a variety of job titles within their individual companies. The goal was to create an apprenticeship program that could be applicable to most careers in manufacturing and could be used to train individuals new to manufacturing and incumbent workers with years of working history. Working collaboratively, WRTP|BIG STEP, employers, and unions identified the basic skills needed for entry-level jobs and what is needed to advance along a career path. WRTP|BIG STEP worked with the Wisconsin State Department of Workforce Development, Bureau of Apprenticeship Standards to design a 3,000-hour hybrid registered apprenticeship with 264 hours of related instruction that would be applicable statewide. They also worked with employers to create the Job Book which identifies approximately 2,700 hours of on-the-job learning that can be adjusted to meet more specific needs within a sector or job.

The IMT program was designed to be very adaptable. The related instruction focuses on safety, quality, production, maintenance, awareness, communications, and industrial math, knowledge, and skills which cut across industries and jobs. On-the-job learning is more focused on a specific industry or technology. The IMT apprenticeship intentionally aligns with existing youth apprenticeships, pre-apprenticeships, more advanced apprenticeships which take four to five years to complete, and union-based training in skilled trades. What this means is individuals who have already completed, for example, a youth apprenticeship, college credits, credentials, and or on-the-job learning, can count this learning and work history towards the IMT, where appropriate. This can streamline and reduce the training load on an individual, reducing the time it takes for them to get placed in a higher paying job.

Along with creating the IMT apprenticeship and other training programs, WRTP|BIG STEP works as a conduit between employers and their future employees. To find potential employees, WRTP|BIG STEP uses the COE, works with city and state workforce boards, community and technical colleges, and is part of the Community Workforce Partnership (CWP), a formal network of community-based organizations developed by WRTP|BIG STEP. They also depend heavily on referrals from individuals who found employment through WRTP|BIG STEP. CWP members offer recruitment, screening, and employment readiness education and training activities, and collectively work on eliminating barriers to employment providing necessary, specialized services for community residents, including transportation, childcare, income, training, and support for re-entering citizens.

Quote:

“When an employer is hiring, we work with partners and search for people that are a reasonable driving distance to that employer. Then we work with partners on eliminating those barriers to employment. We have no geographic boundaries; we align and leverage a variety of funding sources so we can maintain our industry-led worker-centered model, and not be totally grant driven. We really try to look at it as: ‘This employer is hiring, these are the people that want to work there, so how do we make that happen?’”

-Rhandi Berth, Chief Innovations Officer

Keys to Success

Rhandi Berth, WRTP|BIG STEP’s Vice President and Chief Innovations Officer, identified two main keys to success: creating an industry-led and worker-centered training strategy that accommodates employees, and being part of a community-focused network of partners.

One program doesn’t fit everyone. Current and potential employees need different types of training programs depending on, for example, their previous education, work history, family care commitments, and accessibility of funding. WRTP|BIG STEP supports a wide population, from existing employees with a four-year degree to job seekers who did not finish high school. This influenced WRTP|BIG STEP to find a workforce training model that is flexible and can incorporate individual worker history. Another influential factor is that in order to be an apprentice someone has to be employed first, creating a paid-to-learn opportunity making it possible for more individuals to participate. And the registered apprenticeship model doesn’t preclude workers from gaining other industry-recognized learning standards. For example, when working as an apprentice, you complete work hours, take college classes, and learn industry-recognized skills. This means that upon completion a journey worker — the title given to an individual who has completed an apprenticeship — has an accredited certification, as well as industry-recognized credentials, and college credits.

Lastly, WRTP|BIG STEP has created a way to deliver training materials in a flexible way allowing employers and IMT apprentices to get started quickly and continue their learning year round, rather than wait for a semester or academic calendar to start. This is done by working with multiple partners — the main one being a local Manufacturing Skill Standards Council (MSSC) member — who can be brought into a company to teach different elements of the 264-hour curriculum.

Working with partners is not always easy for employers to do when they are focused on running their business. For example, they don't have time to know which college is teaching what. WRTP|BIG STEP acts as a case manager for each employer and an extension of their HR department. Each of WRTP|BIG STEP’s industry staff works with an employer to understand the full spectrum of what they need and then WRTP|BIG STEP helps them find the right partners, workforce, funding, and/or support services. If any question or issue arises with an employer, industry-specific staff members respond immediately with either internal offerings or recommendations for services provided by partners. This requires WRTP|BIG STEP to be up-to-date on what types of support providers are offering, who to contact, and what is expected of the employer in order to work with the partner. Keeping partnership relationships and information up-to-date, according to Berth, is probably the hardest part of their job. Non-employer partner relationships take a lot of nurturing and a lot of attention and it's not always fundable, but it's very important.

Quote:

“Our pre-employment participants were studied after two and three years of participation, to see how employees that were placed with WRTP|BIG STEPs involvement are doing. They had very high retention rates and very high wage placement rates. And that's one of the things we're known for: a reverse workforce model, starting with good jobs and helping employers become better and more inclusive.”

-Rhandi Berth, Chief Innovations Officer

Outcomes

WRTP|BIG STEP wants to not just diversify entry level jobs; they want to diversify higher level jobs. WRTP|BIG STEP identified that the best way to get women and people of color into those jobs is to get them more skills faster, which is why they created the IMT apprenticeship. The IMT apprenticeship, launched in 2012, scaled up quicker than any apprenticeship in the history of Wisconsin and it has been replicated in over 20 states. WRTP|BIG STEP is working directly with employers or an employer through a union representative to bring the IMT apprenticeship into new facilities. According to the Equity in Apprenticeships Report published by the Center of Wisconsin Strategy, which studies workforce and opportunity through an equity lens:

“In 2016, Wisconsin had some 2,265 workers registered in all industrial apprenticeships. With 76 apprentices, the IMT accounted for a tiny sliver — just 3.3 percent — of Wisconsin industrial apprentice participants. But the IMT accounts for one in five of women in the state’s industrial apprenticeships: of the 60 women in industrial apprenticeships, 12 were in the IMT… The IMT is also performing much better than other industrial apprenticeships for people of color. ... [I]t accounts for more than one-in-four workers of color in all industrial apprenticeships (21 of the 82 apprentices of color in the state are in the IMT). … Because the IMT is designed to be a launching pad into further training, in time the diversity of IMT journey level workers may help increase diversity in these more intensive (and traditional) industrial apprenticeships.”

For WRTP|BIG STEP, one of the most important outcomes is that unions and employers keep coming back to find workers and/or to bring in the IMT apprenticeship. When employers keep coming back it shows WRTP|BIG STEP it is worth investing more time and resources to help that company. Increased connections between employers, community partners, unions, and WRTP|BIG STEP has created a more knowledgeable and more aware ecosystem. WRTP|BIG STEP has seen changes within employers, such as better treatment of their employees, an increase in job quality, and more diverse workers being given opportunities. It is difficult to pinpoint one exact reason for these changes, instead it is likely due to a combination of factors: people talk about their work experience with their unions and “high road” companies get more recognition as good places to work; employees are staying at companies longer; and data collection is more consistent, providing proof of success, helping convince manufacturers new changes are worth making. WRTP|BIG STEP now has employers approaching them, voicing interest in creating a better workplace and those that embrace the new approach are seeing the benefits. WRTP|BIG STEP’s work has helped companies learn that investing in worker education is worth doing and that it is worth the extra effort of being flexible and creative to help their employees succeed while learning.

The Future [Scaling]

In Milwaukee, there used to be large manufacturing employers that would take in an employee regardless of their work experience because they had the capacity to train in-house and prepare their own talent. Over time, those employees would leave for positions at smaller companies and move up the career ladder. The smaller companies benefited from the large companies’ on-the-job training and employee development. When the large manufacturing firms started leaving the central cities 25 years ago, the small employers were left in limbo, wondering: Who would teach new people the skills to work in manufacturing? The whole industry had to change its hiring practices. Over the past 10 years, smaller companies have started stepping up to take on the responsibility, and new initiatives like the one designed and developed by the industry convened by WRTP|BIG STEP, the IMT apprenticeship program, and the ecosystem that supports it, are equipping small- and medium-sized manufacturers to train and maintain the next generation of workers.

WRTP|BIG STEP was recently awarded one of the U.S. Department of Labor’s Closing the Skills Gap grants to promote industrial apprenticeships in Wisconsin. WRTP|BIG STEP is implementing a strategy to increase apprenticeships that has not been done before in the state. In Wisconsin, where other apprenticeship sponsors have created and manage union or non-union apprenticeships, WRTP|BIG STEP is operating with a joint labor management strategy creating programs that meet the needs of both union and non-union employers. As an industrial apprenticeship sponsor, WRTP|BIG STEP has been approved for five occupations and they are becoming approved for more. According to the WRTP|BIG STEP’s 2020 industrial needs assessment 80 percent of the 220 employers surveyed were more interested in starting or expanding a registered apprenticeship if a true industry sponsor was developed and available for them to utilize.

Further, the IMT apprenticeship program was designed to be iterated. There could be 30 or more different occupational IMTs without much effort because of everything that was invested into the development upfront. As an industrial registered apprenticeship sponsor, WRTP|BIG STEP can sponsor all kinds of apprenticeable occupations, whenever an employer wants one. WRTP|BIG STEP sponsors the development and brings the proposed apprenticeship before a committee of employers and unions who can approve or deny it; when denied, the committee provides feedback, giving WRTP|BIG STEP the opportunity to iterate and improve. When a new apprenticeship is approved by the committee and the Wisconsin State Bureau of Apprenticeship Standards, it can be implemented immediately by the employer that voiced interest at the beginning of the process. WRTP|BIG STEP takes action, recruiting applications through their networks, and providing employer support and educational partners that can offer existing skills training or the development of new content to match the new apprenticeship iteration.

For WRTP|BIG STEP scalability is about doing a lot more of what they have been doing, and getting more individuals enrolled in the IMT apprenticeship program in the city, state, and across the country. This will require adding new partners and other interested industries and employers. What has allowed this increase is WRTP|BIG STEP’s strategy to think about replicability, scalability, and efficiency from the beginning. WRTP|BIG STEP believes the program will scale itself because those partners that are already involved — employers, unions, community colleges — are helping it scale.

This case study was originally published by Urban Manufacturing Alliance in collaboration with The Century Foundation in 2021 as part of “Manufacturing Workforce Strategies Building An Inclusive Future: How community-embedded workforce organizations center racial equity, credentialing, and training to create stronger neighborhoods,” a report highlighting best practices from eight workforce organizations in connecting diverse communities to opportunities in manufacturing.