How MxD Is Shaping the Future of Manufacturing Through Education and Innovation

Train for what’s next

Brief Introduction, History, & Background

Manufacturing x Digital (MxD), previously called the Digital Manufacturing and Design Innovation Institute (DMDII), is one of 16 Manufacturing USA Institutes, a national network of centers tasked with advancing different aspects of Industry 4.0. Since opening in 2014, MxD has created a state-of-the-art innovation center for industry collaboration with a 22,000 square foot manufacturing floor used to demonstrate cutting edge technology, educate high schoolers, young adults, and incumbent workers, and support research and development of digitally-enhanced technologies. MxD is tasked with helping U.S. manufacturers develop new digital tools to improve different parts of the manufacturing supply chain from tracking materials and products to managing a factory floor to digital simulations that improve training and education. MxD’s research and development work is supported through a multi-year commitment from the U.S. Department of Defense along with its industry partners. In about seven years of operation, its membership network has grown to include more than 300 businesses, academic institutes, and government agencies. In order to increase the adoption of digital technology and cybersecurity in manufacturing, as well as to create sustainable American manufacturing jobs, MxD is also involved in workforce development initiatives. MxD Learn, MxD’s workforce development program, is prioritizing under-resourced communities that historically have lacked equal access to high-tech career pathways. In 2019, MxD launched IGNITE at Waukegan high school, one of Illinois' largest Title 1 schools, at which 58% of the students are considered economically disadvantaged and minority enrollment stands at 97%.

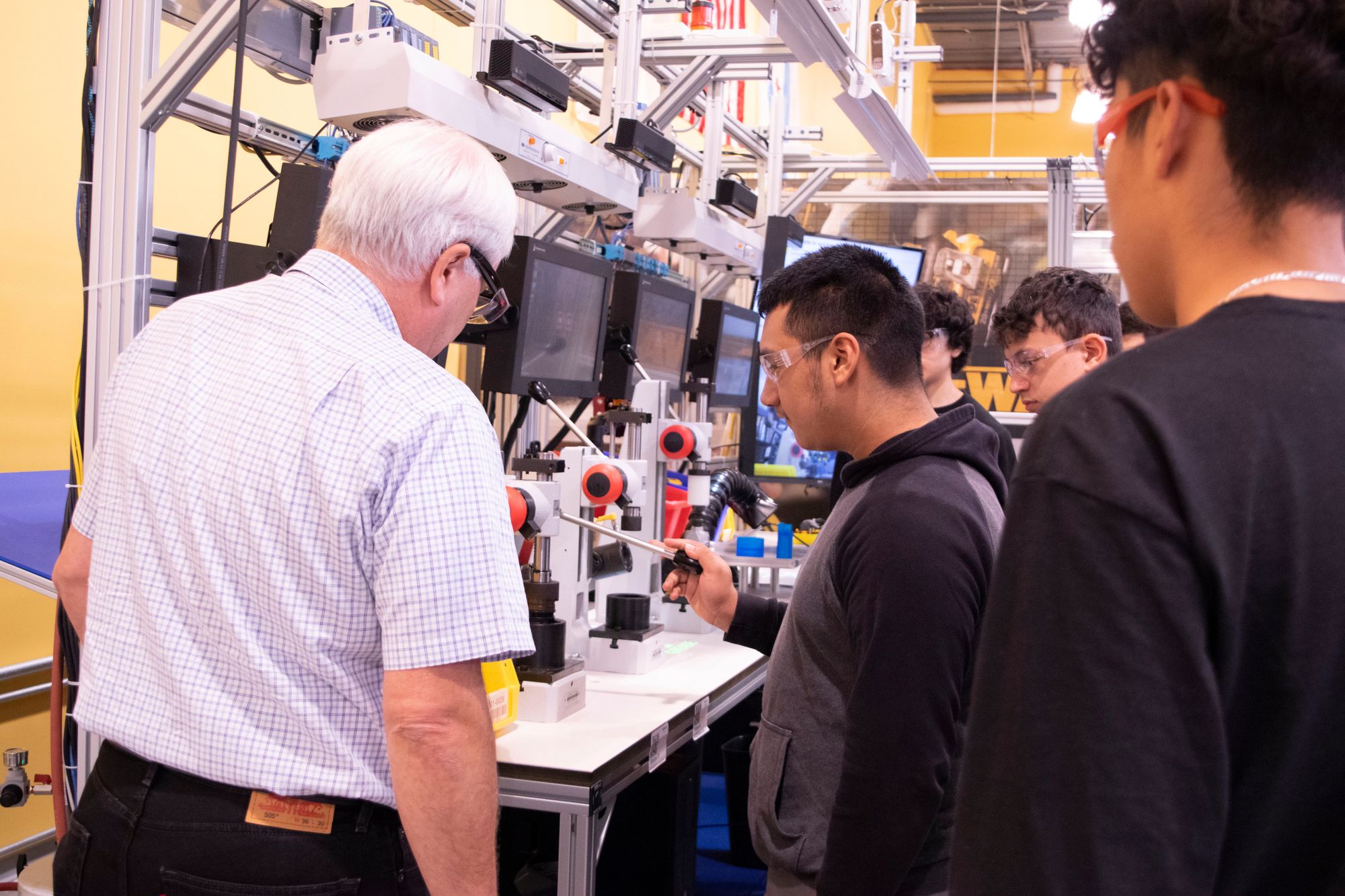

MxD Learn began building out new frameworks to career pathways in digital manufacturing through a collaboration with ManpowerGroup. Together, the organizations created a digital workforce taxonomy, a report documenting 165 new data-centric manufacturing jobs, running from “collaborative robotics technician” to “predictive maintenance systems specialist.” The taxonomy is a valuable resource for understanding skill sets that cut across industry domains and job titles, and which skills are specific to niches within a certain sector of advanced manufacturing. MxD Learn expanded its workforce development offerings when the factory floor manufacturing testbed opened in 2015. At MxD’s facility in Chicago, students and workers can participate in a range of activities and events, from a factory tour to hands-on training. The factory floor continues to add technologies: since the innovation center opened its doors, additions include a digitized manual assembly testbed, a discrete manufacturing testbed, and cybersecurity for operational technology demonstrations. MxD partners AT&T, Autodesk, Fast Radius, McKinsey & Company, Microsoft, Siemens, and Software AG also have dedicated space on the floor to showcase innovative manufacturing technologies. Each additional testbed and demonstration within the larger factory floor increases the opportunities for MxD to advance Industry 4.0 and train future talent.

Lizabeth quote:

“The employers in the region have a need to hire. Our aspiration is to engage young people in high school to get them excited and wanting to work for these employers. To do that we bring in the community college, the high school, faculty, and community leaders. We are trying to bring the whole community.”

About MxD Learn

MxD’s early work with its digital manufacturing jobs taxonomy, followed by the Hiring Guide: Cybersecurity in Manufacturing, released in 2019, establishes a framework for MxD Learn. These resources provide an outline of what skills and knowledge need to be introduced via their programs including IGNITE and FlexFactor. To create and deliver these programs, MxD Learn fosters collaboration and takes on the role of convener. To provide insights to translate into educational content, MxD can tap into its member network consisting of manufacturers, universities, and non-profit and governmental entities in the Chicago region and beyond.

MxD Learn engages with high school students outside its headquarters through IGNITE: Mastering Manufacturing. IGNITE is a three-year high school curriculum developed in collaboration with Detroit-based LIFT (also a Manufacturing USA institute), community colleges, and high schools. IGNITE uses in-class industry-based projects to teach high school sophomores, juniors, and seniors skills that prepare them for careers in manufacturing while establishing connections for employment opportunities. The curriculum is designed to prepare students to become multiskilled technicians, technologists, and engineers. Students starting in their sophomore year can choose to take manufacturing-focused elective courses. These classes go beyond just increasing awareness; teachers are helping students develop core skills. Students learn through hands-on experience with technology used today in advanced manufacturing companies. The technology is accessible via two new technology labs at Waukegan High School. The lab was created by converting an old woodshop, the funding for which came from a large investment from the community -- including donations from Lake County Partners and the Siemens Foundation. The classroom and high school lab learning are supplemented by factory tours, demonstrations at MxD’s factory floor, and presentations by subject matter experts. At the end of their three years, the IGNITE cohort culminates in a team capstone project where students apply what they learned about digital manufacturing and cybersecurity to an industry problem showcasing their deep understanding of manufacturing materials, technologies, processes, and systems.

FlexFactor is MxD Learn’s next educational program. The FlexFactor program is based on a model developed by NextFlex (a Manufacturing USA Institute). The model was first tested in 2015 and in five years 3,209 K-12 students in the San Jose, CA, region have participated. In 2020, NextFlex developed a strategy to deliver the program virtually. In 2021, MxD and six other Manufacturing USA Institutes will implement the FlexFactor model, with each institute augmenting it to focus on their specific expertise. FlexFactor is similar to IGNITE as both are engaging students and creating awareness. The biggest difference is the time frame; FlexFactor is a one semester long program rather than three years. Students can participate by signing up for the elective, rather than being in a cohort. In that semester they are introduced to manufacturing careers through virtual tours, subject matter expert discussions, and technology demonstrations. The students take what they have learned, team up, and create their own product. The semester concludes with a pitch session to industry leaders and the Manufacturing USA Institute that hosts the program. In spring of 2021, MxD will lead a collaborative process to create a FlexFactor iteration focused on digital manufacturing and cybersecurity content. And in the Fall, the initial launch will be done with a regional high school as a test run.

MxD Learn’s specific responsibilities in both programs run throughout all stages: curriculum and course development, educating students, and post-graduation opportunities. At the start, MxD brought together industry partners, community college faculty, high school teachers, and MxD staff to co-create individual course content, project briefs, and the overall three-year curriculum. Now that the program is up and running, MxD is involved with educating students. MxD hosts virtual demonstrations and discussions and creates tool kits for hands-on remote learning, all due to COVID. MxD is already planning for the first cohort of students to graduate in 2022 and will use its membership network to create pathways for early career success.

Michael quote:

“The FlexFactor program empowers students to create their own solutions. Instead of us going to a school and saying this is what you need to know, students are building leadership skills demonstrating how to be innovative. Today’s high school students are digital natives and don’t have the fear of using digital technology. Their creativity in understanding and applying digital technology solutions can help show industry what is possible.”

Keys to Success

Early in MxD’s development three goals were identified as framing success: programs must be industry-driven, engage with the community, and reach diverse students. These help frame a holistic approach to developing, executing, and assessing successful programs. MxD believes if these goals are met, it leads to the creation of meaningful workforce opportunities for the individuals going through the training and providing meaningful service to the employers who are looking to hire. Collaboration is necessary for all of MxD Learn’s work to come together. This means getting feedback from external partners, MxD Learn staff, MxD team members on the technology research and development side, MxD members, and students. This process allows everyone to have a shared goal but bring different perspectives in achieving it.

One way to make sure they meet their goals is by having a career pathway or blueprint strategy in mind. This means creating a series of stepping stones a student can follow. It is relatively easy to create an event that incites excitement and interest, but if you don’t create a place, space, or resource for someone as an immediate next step then that excitement, interest, and connection is likely lost. MxD is responding by hosting many types of events to get people introduced to careers in manufacturing, then offering the next stepping stone via workshops and demonstrations on its factory floor. For educators and administrators that get excited, they have the opportunity to bring IGNITE or FlexFactor to their school. This also applies to manufacturing businesses. It is possible for them to go through the same cycle: they see a technology, or hear about a creative workforce development solution, and get excited, but can’t find an expert and supporter to help integrate new technology or new workforce then momentum is lost. For manufacturers, the taxonomy report is an immediate resource, with the factory floor, membership, and opportunities to contribute to educational programs being second and third possible stepping stones to get support for adopting new innovation.

MxD considers its ability to innovate across the workforce development system as a key to success. A lot of workforce development support is offered only if there is data showing a historic or current demand for a skill set. MxD’s industry engagement work starts with R&D and understanding technology in future factories. This work shows where the industry is going, and shows an industry demand for skills needed soon. Workforce development can be challenging because you are working to meet the needs of industry and of middle and high school students. It requires understanding two very different stakeholder groups in the now, as well as predicting how industry will change and what people will need as they move to the next stage of their lives. This puts MxD in the position to find innovative ways to impact the system as a whole. By going into high schools, they are creating a demand for more educational opportunities and creating the next innovators who will define the next R&D and the design of the future factory. Over time, if successful, this strategy will create a positive feedback loop changing the way we think about workforce development. Students in high school will learn skills to operate technology while also finding new ways of applying it. They will take this know-how into a career and shape how the industry and individual companies operate, defining the next round of technology and skill sets to be taught to the next students.

Lizabeth quote:

“I worry that if you only provide an introduction to manufacturing to a student then you are missing the chance to get them more deeply involved. You can bring a student into a manufacturing facility and they might say ‘I would really like this work’ but if you leave at the end of the day, and don’t provide a next step their interest may be lost. We have to give them a next step, a pathway. We try to have our program support that model; we create the next step, then the next, and the next.”

Outcomes

MxD’s first implementation of IGNITE with Waukegan High School in 2019 included over 150 students. With COVID drastically impacting high school education, MxD pivoted to find ways to continue delivering education and opportunities, while also learning from its early findings. The original classroom teaching utilized a lot of self-directed learning, which had mixed success. Without the ability for students to be in the lab spaces in their school, that strategy was made even more difficult. MxD pivoted to the development of individual toolkits for each student, allowing them to learn at home and do hands-on learning while also learning as a group via video classes. They are considering individual toolkits and a more directed learning strategy even when in-person learning resumes. This ability to test and change in a short amount of time - the program was running for only six months before COVID impacted their work - shows MxD’s willingness to learn and grow.

In the course of building relationships to create and deliver IGNITE, the MxD team learned that College of Lake County, just a few blocks from Waukegan High School, was in the process of building a new mechatronics degree program and lab. This connection led to identifying overlap between the IGNITE high school curriculum and the one that was about to be offered at the community college level. Together, they aligned course content to allow high school students to be dual enrolled and get college credit via their IGNITE electives. This early success has driven the exploration of new connections between ninth through twelfth grade learning and community college education. MxD has since begun to work with the community college to develop an apprenticeship program in cybersecurity and digital manufacturing that is also in line with future College of Lake County offerings. When the new apprenticeship program is running, it will mean Waukegan high school students have the chance to start their careers in manufacturing while continuing their education. It will also create new opportunities for students across the district even if their schools are not participating in the IGNITE program.

The Future [Scaling]

A key question MxD Learn’s staff asks when developing any program is: Is there any opportunity to scale up beyond where we first start? One of the things that makes MxD valuable is that it is a national organization. The institute is looking at workforce challenges and solutions with a national lens while developing a community approach to creating and delivering a solution. This informed why MxD has collaboratively worked with LIFT and NextFlex. All three institutes are able to test and learn in a specific location and then explore how to bring the learning models to other regions. This collaboration also means individual schools that have already adopted IGNITE and FlexFactor will have new courses and curriculum to offer, like digital manufacturing and cybersecurity.

COVID disrupted a lot of the hands-on learning that is necessary for skill development, but it also led to a huge leap in virtual, distributed learning. MxD is exploring how to use virtual, synchronous, and asynchronous learning to connect their industry, government, and academic members, who are all across the country, with high schools and colleges within their respective regions. The Institute is exploring how to provide some resources and tools that make it easier to access these programs. This opportunity could mean an individual young person could engage even if their high school is not participating, as well as could offer employers and incumbent workers new training opportunities. MxD is exploring what kind of platforms and resources are needed to provide increased accessibility to these programs.

MxD is quick to point out that the current and future success all depends on relationships. Relationships with students, parents, and teachers were often started with visits to the innovation center, which had over 1,000 visitors a month pre-pandemic. MxD Learn is in the process of rethinking outreach. Another set of relationships to build is with high schools interested in hosting IGNITE classes and cohorts. Waukegan became the first high school to participate in large part due to the Career and Technical Education (CTE) director who was very passionate about the opportunity. He took the chance to work with MxD and ran with it. Expanding to new schools will require finding that leader willing to stand up and make it happen, or will require finding ways to communicate with schools about the opportunities to get teachers and administrators excited. Moving to other regions will also require understanding how curriculum development and adoption occurs, a factor that was made apparent when working through the initial implementation. MxD had worked with industry to validate the curriculum, but when it was presented to the high school, the high school also wanted to know that the curriculum was validated by the community college.

The last set of relationships that will be key to scaling is those involving industry partners. MxD has a very strong partnership with the Siemens Foundation, and with Siemens cybersecurity office for North America, and they are exploring ways to expand that relationship and with other large industry partners. But there is no “one size fits all” way to work with partners, so it will take time and a number of shapes and forms. Successful partnerships depend on the sector, the company size, and the region. There are a lot of factors that can either help or hinder engagement. MxD Learn is also exploring academic and nonprofit engagements. Since its launch, MxD has used collaborative research and development projects, multifaceted programming, and strategic outreach to build its ecosystem of hundreds of partners from dozens of states, spanning coast to coast. This network forms a strong foundation to leverage relationships with stakeholders committed to driving America’s digital manufacturing forward into education and workforce collaborations.

This case study was originally published by Urban Manufacturing Alliance in collaboration with The Century Foundation in 2021 as part of “Manufacturing Workforce Strategies Building An Inclusive Future: How community-embedded workforce organizations center racial equity, credentialing, and training to create stronger neighborhoods,” a report highlighting best practices from eight workforce organizations in connecting diverse communities to opportunities in manufacturing.