Building the Future: How LIFT is Transforming Manufacturing Education and Workforce Development

Driving American Technology and Talent Into the Future

Brief Introduction, History, & Background

Since its founding in 2014, Lightweight Innovations For Tomorrow (LIFT), the Detroit-based, Department of Defense-supported national manufacturing innovation institute, has invested in more than 40 replicable and scalable education and workforce development initiatives which have been deployed, tested, and refined throughout the midwest region. All programs were focused on developing an advanced manufacturing talent pipeline. The focus on workforce was one of the original tasks defined on day one of LIFT opening its doors. LIFT was one of the first three National Manufacturing Innovation institutes formed. In the seven years LIFT has been operating, they have been able to organize and work with over 150 partners and industry stakeholders to inform the development of its education and workforce development strategies.

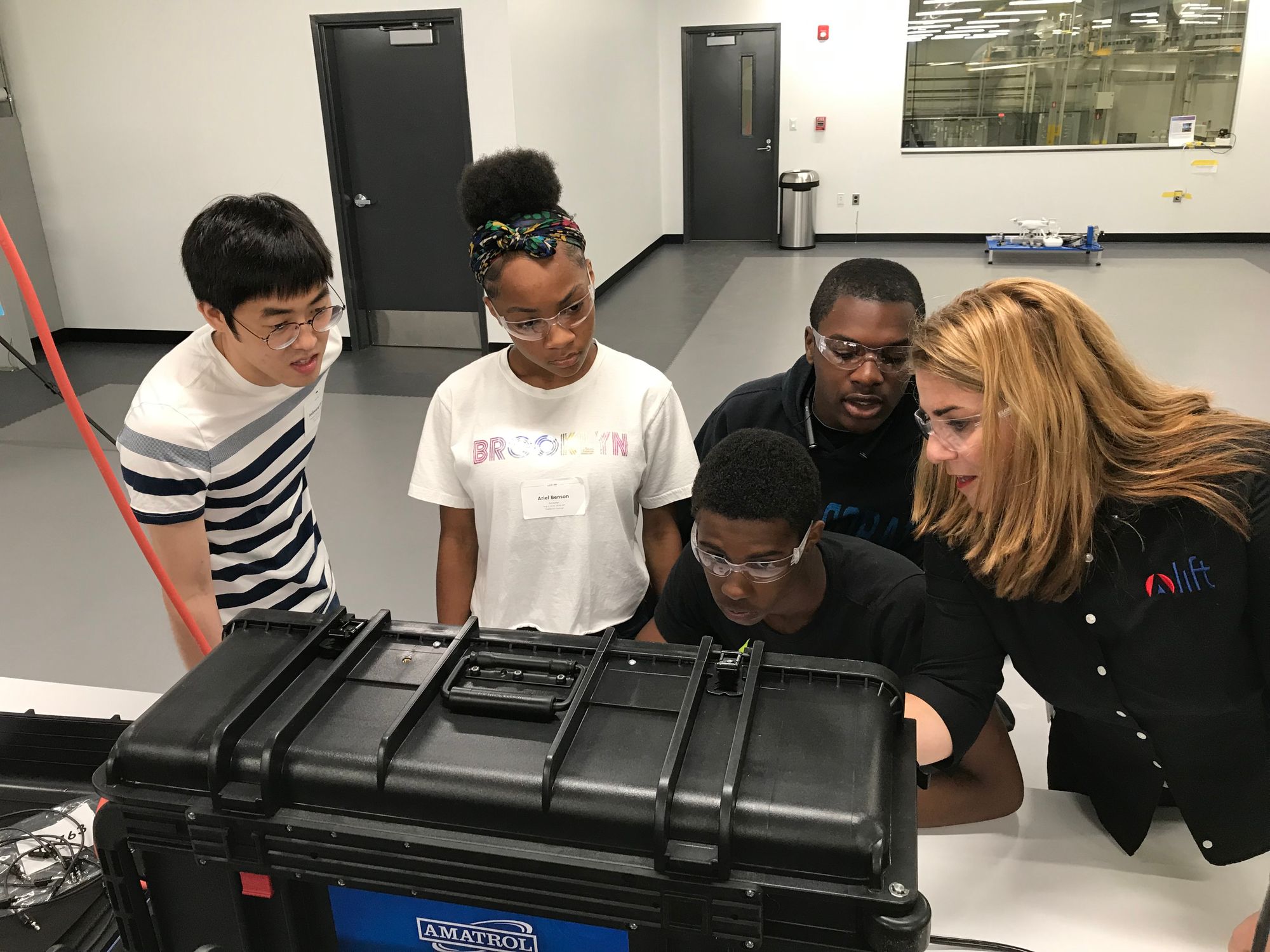

In 2019, LIFT launched the Learning Lab, an immersive learning facility with seven unique labs, such as: Smart Factory Digital Twin Lab, Fundamental Skills Development Lab, ASM Materials Science & Project Fabrication Lab. Labs are equipped with a wide variety of computer controlled technology from progressive sheet metal forming to drill presses, from plasma treating to extrusion presses, and from welding to flexible joining. Within those labs, LIFT delivers IGNITE, a curriculum which uses real industry challenges to prepare students for the most in-demand manufacturing careers. The Lab and the curriculum create engaging, technology-infused learning experiences inspiring students and encouraging participation in learning. Students are exposed to materials, technologies, processes, and systems, equipping them for success in careers as multiskilled technicians, technologists, and engineers. LIFT also delivers its Operation Next program, designed to train individuals for the most in-demand technician careers, in the Learning Lab.

In the first year of operation, LIFT launched multiple partnerships with local schools and community based organizations to provide immersive manufacturing learning experiences for students in the Learning Lab. One partnership with University Prep Academy, the largest charter school in the City of Detroit, resulted in 80 students completing performance-based training on the IGNITE curriculum in the LIFT Learning Lab daily. 100% of the students that enrolled in the UPrep IGNITE program were Black youth from low income communities. Additionally LIFT is training 30 individuals in Operation Next training program, with those individuals earning industry-recognized credentials in CNC Operations or Welding.

Both the IGNITE:Mastering Manufacturing and Operation Next programs are being implemented beyond the Learning Lab by educational providers nationwide.

About IGNITE and LIFT Learning Lab

LIFT developed IGNITE: Mastering Manufacturing, a three year program, to introduce students to technologies, concepts, and processes that are necessary for a successful career in manufacturing today and into the future.

The IGNITE program provides much needed STEM-based education and career path exposure to students from the city’s communities that have historically been left out of advanced manufacturing opportunities. In Detroit’s high schools, 79% of the population is Black, and 11% is Latinx. In the foundational year of IGNITE, students are introduced to materials, materials science, and engineering design processes. This includes deep dives into many types of banal and cutting materials. In parallel, students learn the importance of observing and documenting their work and learning process. The second half of the year introduces key skills in safety and measuring, technical skills like CAD/CAM programming, robotics, understanding electricity and fluid mechanics, and higher level concepts in manufacturing like plant organization. In year two, students take advanced classes in topics introduced in year one and are introduced to lean manufacturing practices. In year three students work in groups to complete a capstone project, a project that builds on their existing skills from years one and two, while giving them new abilities to problem solve and work with industry specific and emerging technologies.

Jacqui:

“If you are pursuing a career in the advanced manufacturing space you have to be engaged in ongoing education. The pace of technology is changing so quickly, it is not realistic to think it will be the same thing forever. This requires people to embrace wanting to learn and keep up with technology and requires workforce development programs to be open to ongoing improvements.”

Operation Next is an accelerated hybrid training model combining virtual learning with hands-on performance-based training. The program was originally designed to train active duty military in their last six months of service to earn industry-recognized credentials in CNC machining, industrial technology maintenance, welding, or robotics. Operation Next is being expanded to also serve National Guard and Reserve members, military spouses, and more recently civilians impacted by the COVID-19 pandemic.. The curriculum, delivered to all target audiences aligned to industry-recognized credentials defined by National Institute of Metalworking Skills (NIMS) and American Welding Society (AWS).

LIFT is able to deliver these training programs in-house via the Learning Lab, a 6,500 square feet, state-of-the-art interactive learning facility, located in the LIFT Manufacturing Innovation Institute. With these learning facilities co-located in LIFT’s state-of-the art smarter manufacturing innovation lab, LIFT’s students are exposed to new technologies and cutting-edge processes while learning the fundamentals they need to thrive in an advanced manufacturing workplace. The technology is being developed by LIFT members, a blend of for profit companies, academic institutes, and government agencies. This means LIFT is always working with both industry-ready and next-generation technologies. To provide the training and instruction, LIFT depends on a network of contracted instructors rather than staffing teachers themselves. LIFT only has one staff member dedicated to the Learning Lab, a manager, with 15 years of experience in education, who helps run the day-to-day operations. She provides some co-teaching and co-curriculum development when needed. The manager builds relationships with instructors and hires them on a contract basis. For example, one of the instructors for their welding program teaches welding at a high school and one instructor in a CNC training program is an adjunct professor at a community college. In the IGNITE program, technical instructors collaborate with teachers from the high school where students are enrolled to deliver all aspects of the education and student support. The combination of the IGNITE curriculum and the Learning Lab provides a unique learning environment where students gain insights into manufacturing skills and careers as well as exposure to the design and engineering of technology.

Keys to Success

For LIFT to succeed in developing workforce training they knew from the beginning that it had to look different. Their goal was to work with partners in the region to do something innovative, rather than parachuting in with the new solution. In the first years of work, LIFT worked with over 150 stakeholders across five states to launch pilot 40 programs. The ongoing relationship with local industry partners, members of LIFT, and technology developers helps to make sure the curriculum and skill development is inline with what is needed for immediate job placement and lasting success.

Similarity, LIFT took an open approach to creating the Learning Lab. From the start, LIFT wanted the Learning Lab to be seen as a community asset, to have it be an educational space, not just an activity space or a space just for industry and technology. Getting students in the door took some effort. LIFT originally approached several school systems in the region about using the LIFT Learning Lab as a performance based training center for their students. After nearly 18 months of planning, LIFT ultimately partnered with University Prep Academies, Detroit's largest charter school system. However, several barriers to partnership were identified, including finding transportation to students. The Skillman Foundation - a non-profit helping Detroit children gain access to educational and economic opportunities - provided support to cover the cost of transportation and within a couple months students from University Prep Academies were attending classes at the Learning Lab. This led to the first cohort of high school students starting the three year curriculum in 2019.

LIFT is aware that technical training is only one aspect of making sure that people are successful, and that individual students need help not just getting a job but being successful in their careers long term. To help achieve this, LIFT has developed a relationship with local Michigan Works! Agencies, (Michigans’ Workforce Investment Boards). Through this partnership students can get help identifying other supportive and wraparound services. This allows LIFT to focus on the training and the WIB can help connect the dots and identify, for example, financial aid, transportation assistance, child care assistance, and financial literacy planning for students in any target group. While many might first approach the WIB for funding to cover training costs, it typically goes beyond that, it becomes another layer of support and coaching which increases student’s abilities to commit and succeed.

Quote:

“It is a challenge to find an instructor that knows how to weld, or be a CNC operator, has teaching abilities, and then add to that, the ability to work with students of all ages who have experienced trauma. It is difficult to find the unicorn instructors and so we are looking at resources to help our instructors, at LIFT, and those involved in the workforce development in the region”

-Jacqui Micksztyn, Talent & Workforce Strategist

Outcomes

Since launching the Learning Lab in summer of 2020, LIFT has also trained 10 students in welding and CNC Operations, earning relevant industry-recognized credentials. While LIFT has been impacted by restrictions from the COVID-19 pandemic, pausing in-person learning for much of 2020, LIFT was to continue to offer virtual components of both IGNITE and Operation Next. 45 students remain enrolled in IGNITE through the partnership with UPrep. Technologies like Siemens Digital Twinning have allowed LIFT to provide students cutting edge virtual learning experience using technology that is being adopted globally as an industry standard -- now much more rapidly because of the pandemic.

LIFT’s impact beyond the number of students trained can be seen in the stakeholder network they have built and continue to learn from and with. In their short history, they have worked with over 150 education and workforce development stakeholders in Michigan, Indiana, Ohio, Tennessee, and Kentucky to launch educational workforce and technology development support. This network has allowed LIFT to explore the deeper question: how do you create workforce development programs around technology that is constantly changing and reframing the skills necessary for a career in manufacturing?

The Future [Scaling]

LIFT from the outset had a focus on scaling their programming. This led them to build their IGNITE curriculum and Learning Lab using a modular approach, making it possible for other cities, states, or regions to adopt and implement some or all modules. The curriculum, as seen at LIFT’s Detroit HQ, can be modified for different age groups and student backgrounds, from high school to community college to workforce development models, whereas the different labs that make up the larger Learning Lab can be established individually or together. The modularity also allows different partnerships and stakeholders to take shape. The Operation Next program is scaling to new military bases around the country, including expanding to communities with significant national guard presence, creating new partnerships at each location between the military, technical instructors, and industry. There is also a project supported by National Institute of Standards Technology (NIST) to use the same structure as Operation Next but to bring it to small and medium manufacturers, to help them retrain their incumbent workforce, specifically individuals who have been displaced because of COVID. One pilot program in Pittsburgh, PA is bringing together ARM (Advanced Robotics for Manufacturing, another Manufacturing U.S.A. institute), university partners, and regional industry.

Another scaling strategy is to increase the number of students learning at the Lab and to have the space fully utilized. Currently the interest is there, and increasing use will require building new relationships with charter schools like University Prep and finding ways to navigate previous barriers to working with the public school system. While virtual classes and learning was not part of their original vision, what they have learned out of necessity has opened up the possibility of ongoing online learning even after the COVID-19 related restrictions have been removed.

Jacqui Quote:

“Getting industry engaged with new workforce programs, especially those designed to prepare a talent pipeline into the future, can be a tough sell. Manufacturers, especially small and medium-sized manufacturers, are so (rightfully) focused on their immediate workforce needs they often aren’t looking further out to their longer term needs. It’s a challenge to demonstrate the value and ROI to companies to get them involved and invested in developing their workforce.”

Lastly, getting industry more engaged will help scale outcomes and program opportunities. The early partnerships that LIFT built were from the education and workforce development sector, local workforce boards, community colleges, universities, and some community development organizations. These partners were vital in helping provide clarity on what to teach, how to teach it, and who to focus on. But as with most new approaches to workforce development, some manufacturers are engaged and onboard from the beginning but the majority are hesitant to get behind an initiative without a track record. LIFT is fortunate to have found some early adopters, through the Aluminum Extruders Council and because of their use of Siemens twinning technology. The belief is, as more students (in all three tracks) complete the programming, LIFT can generate a track record of placements and success, which will draw in more manufacturers and industry partners, increasing demand for skilled graduates, and therefore increasing the resources available to get more people engaged and learning.

This case study was originally published by Urban Manufacturing Alliance in collaboration with The Century Foundation in 2021 as part of “Manufacturing Workforce Strategies Building An Inclusive Future: How community-embedded workforce organizations center racial equity, credentialing, and training to create stronger neighborhoods,” a report highlighting best practices from eight community-driven workforce organizations in connecting diverse communities to opportunities in manufacturing.